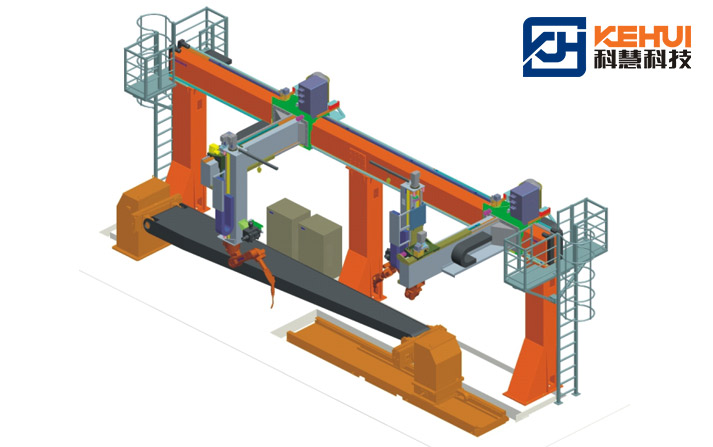

Cement Pump Truck Collaborative Welding Robot

The cement pump truck collaborative welding robot cell is equipped with weld location software and spot welding tracking software. According to the different parts of the cement pump truck, it is divided into the connecting parts robot welding workstation, pump truck leg robot welding workstation, pump truck arm robot welding workstation, turntable robot workstation, and support table robot welding workstation. Different layout forms and robot installation methods are adopted, and the two-axis positioner and the single-axis positioner with walking axis are used to effectively meet the welding tasks of various parts of different models of cement pump trucks.

Application:

The Cement pump truck collaborative welding robot cell is widely used in cement pump truck connection welding, pump truck leg welding, pump truck arm welding, turntable welding, support platform welding, bicycle parts welding, electric vehicle parts welding, guardrail welding, agricultural machinery welding, engineering machinery welding, furniture parts welding, auto parts welding, car seat welding, sports equipment welding, medical equipment welding, hardware and electrical welding, etc.